So in summary, the overhead rate formula relates your indirect operating costs to production costs. The production head wants to calculate a predetermined overhead rate, as that is retained earnings balance sheet the main cost allocated to the new product VXM. For example, the recipe for shea butter has easily identifiable quantities of shea nuts and other ingredients.

Ask Any Financial Question

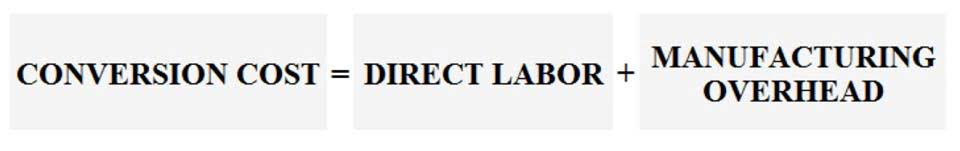

Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs. Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing.. The predetermined overhead rate is a per-unit rate used to allocate overhead costs to products predetermined overhead rate or services based on a predetermined estimate of activity. It serves as a guide for assigning indirect costs to cost objects, such as products, based on a chosen allocation base, typically direct labor hours, machine hours, or direct labor costs.

Leveraging Accounting Software for Overhead Management

- As the predetermined overhead rate is an estimate of what the company believes will be the cost for manufacturing the product, the actual costs could be different than what they estimated.

- The example shown above is known as the single predetermined overhead rate or plant-wide overhead rate.

- Small companies tend to use activity-based costing, whereas in larger companies, each department in which different processes of production take place typically computes its own predetermined overhead rate.

- For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March.

The predetermined overhead rate formula is calculated by dividing the total estimated overhead costs for the period by the estimated activity base. For the last three years, your team found that the total overhead rate has been between 1.7 and 1.8 times higher than the direct materials rate. As such, you and your peers have agreed to set the Bookstime predetermined overhead rate at 175% of the direct materials rate. As the predetermined overhead rate is an estimate of what the company believes will be the cost for manufacturing the product, the actual costs could be different than what they estimated.

Concerns Surrounding Predetermined Overhead Rates

Its production department comes up with the details of how much the overheads will be and what other costs will be incurred. Small companies typically use activity-based costing, while large organizations will have departments that compute their own rates. Different businesses have different ways of costing; some use the single rate, others use multiple rates, and the rest use activity-based costing.

Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor. The price a business charges its customers is usually negotiated or decided based on the cost of manufacturing. This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit. Hence, one of the major advantages of predetermined overhead rate formula is that it is useful in price setting. Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs. This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead costs incurred.

- When there is a big difference between the actual and estimated overheads, unexpected expenses will definitely be incurred.

- Based on the above information, we must calculate the predetermined overhead rate for both companies to determine which company has more chance of winning the auction.

- To account for these changes in technology and production, many organizations today have adopted an overhead allocation method known as activity-based costing (ABC).

- Therefore, the predetermined overhead rate of GHJ Ltd for next year is expected to be $5,000 per machine hour.

- A predetermined overhead rate is an allocation rate given for indirect manufacturing costs that are involved in the production of a product (or several products).

- The predetermined overhead rate was found by dividing the estimated manufacturing overhead cost by the estimated total units in the allocation base, so the predetermined overhead cost per unit is $9.00.

Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs. Properly calculating and applying overhead rates is an important accounting process for businesses to absorb indirect costs into their job costing system and product pricing. There are concerns that the rate may not be accurate, as it is based on estimates rather than actual data.

- For example, the total direct labor hours estimated for the solo product is 350,000 direct labor hours.

- Overhead costs are those expenses that cannot be directly attached to a specific product, service, or process.

- In larger companies, each department in which different production processes take place usually computes its own predetermined overhead rate.

- The formula seems simple – total overhead costs divided by an allocation base like direct labor hours.

If an actual rate is computed monthly or quarterly, seasonal factors in overhead costs or in the activity base can produce fluctuations in the overhead rate. For example, the costs of heating and cooling a factory in Illinois will be highest in the winter and summer months and lowest in the spring and fall. If the overhead rate is recomputed at the end of each month or each quarter based on actual costs and activity, the overhead rate would go up in the winter and summer and down in the spring and fall. As a result, two identical jobs, one completed in the winter and one completed in the spring, would be assigned different manufacturing overhead costs. To avoid such fluctuations, actual overhead rates could be computed on an annual or less-frequent basis.

How do you calculate overhead activity rate?

- When companies begin the planning process of manufacturing a product, cost projections are a large and important focus.

- If the predetermined overhead rate calculated is nowhere close to being accurate, the decisions based on this rate will definitely be inaccurate, too.

- The predetermined overhead rate is used to price new products and to calculate variances in overhead costs.

- Using the Solo product as an example, 150,000 units are sold at a price of $20 per unit resulting in sales of $3,000,000.

- Therefore, the one with the lower shall be awarded the auction winner since this project would involve more overheads.

Now management can estimate how much overhead will be required for upcoming work or even competitive bids. For instance, assume the company is bidding on a job that will most likely take $5,000 of labor costs. The management can estimate its overhead costs to be $7,500 and include them in the total bid price. The predetermined rate is also used for preparing budgets and estimating jobs costs for future projects. Most companies will adopt the use of predetermined overhead rates in order to know how their products are performing even before the accounting period ends.

The following exercise is designed to help students apply their knowledge of the predetermined overhead rate in a business scenario. The articles and research support materials available on this site are educational and are not intended to be investment or tax advice. All such information is provided solely for convenience purposes only and all users thereof should be guided accordingly.